Home > Factory Tour > Quality

Our company sets a long-term goal of gaining a leading position in the market of contract parts manufacturing. In order to achieve this, we always try to provide our customers with the best services, being a reliable and punctual partner. Our team always puts the customer's needs first and do our best to meet them. Therefore, at quality precision Machining, we believe that the quality control process at every of its stages is as important as the production itself.

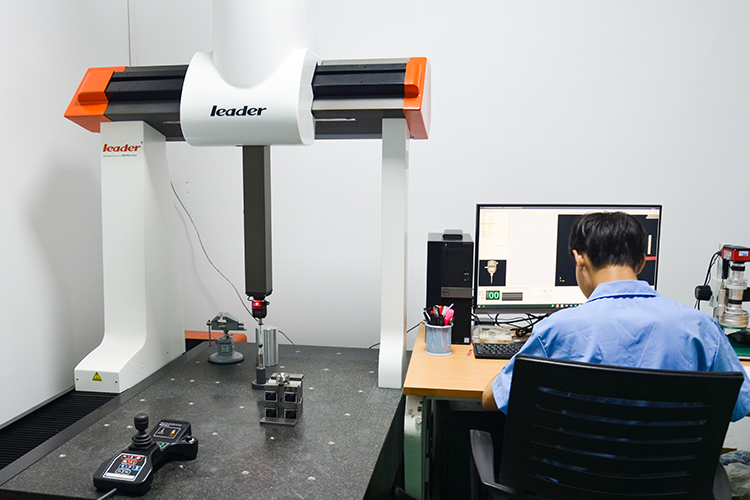

We use the coordinate measuring machine Mitutoyo Euro M574 for the implementation of instrumental 3D control of the produced components

We use a coordinate measuring machine at three stages of the production:

1. When setting up the machine and making a test part. We check the compliance of the test sample before the starting of mass production.

2. On intermediate quality control. We check randomly selected parts from the batch.

3. On the final quality control. We selectively check the details of the party.

The use of instrumental 3D control allows us to start the production of a new part faster and to control the quality more carefully. Therefore, we spend less time on the batch production than other manufacturers.

The coordinate measuring machine allows us to check several sizes of a detail at once in one operation. It helps to control very difficult tolerances. The instrumental method allows to significantly reduce the influence of the subjective human factor. Quality control is faster and more accurate.

We also use a wide range of other modern high-precision measuring equipment. All calipers, micrometers, gauges and other devices are constantly monitored and tested.

The frequency of measurements depends on the stability of the processing of a particular part. Depending on the configuration, material, applied processing method, tool, and other factors, the stability of processing could be changed. The machine operator monitors these parameters in real time and makes corrections. He constantly monitors the quality of finished products. If even the slightest deviation is noticed, the quality control engineer intervenes in the process. After careful checks, the CNC programmer makes changes to the processing programs. The coordinate measuring machine allows to define the reason for the unstable processing process faster and to eliminate it faster.

We do not stop in development even for the moment. In the near future we have to replenish the fleet of devices, tools and other equipment to ensure quality control. We are constantly striving for excellence to fulfill our mission – to help our customers receive parts and components on time.

At Qijia, we control the quality of our products at all stages: starting with the receiving raw materials and up to packaging of finished parts. Our quality management system fully complies with the BS EN ISO 9001: 2015 standard.

We do not stand still, but instead we are constantly developing our quality control system.

Our company partners only with leading EU suppliers of raw materials. Each batch of the supplied material is thoroughly controlled in accordance with customers' requirements.

The following quality control stages are implemented at our production site:

Of course, even the best system can fail sometimes. People say that only those who do not work do not make mistakes. That is why an efficient response to complaints is our highest priority.

We try to find the solution within one business day after receiving such a letter. And of course we try to meet our client halfway, offering the best possible solution.

Our company doest its best for our client to receive only the parts of high quality that fully meet his requirements, because we ourselves are extremely interested in the development of our partner's business. In our opinion, this is the way to success in the realities of the modern business market.

We are well aware of the fact that in some cases the customer can require additional certificates for materials or finished products in order to comply with the requirements of government or other regulatory authorities. Our team is always ready to help to resolve this issue. Just contact our managers, they will be happy to assist you and provide with all the necessary documents.

Dongguan Qijia Precision Technology Co., Ltd.