Robust Grinding Services Service

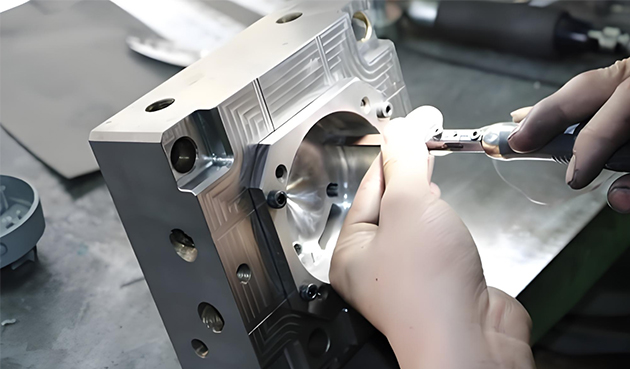

In the pursuit of the ultimate quality and fine manufacturing on the road, mold grinding technology with its exquisite technology and unremitting pursuit, has become a key link to shape the perfect form of products.

Our Grinding Services

Mold grinding, with advanced equipment and technology, accurate correction of mold surface, to achieve high precision and finish. We strictly control the grinding process, from rough grinding to fine polishing, every step is the pursuit of perfection. Exquisite technology combined with rigorous attitude to ensure the mold wear resistance, corrosion resistance, prolong service life, improve product accuracy and quality.

CNC Common Materials

Metal

- Aluminum (4 types)

- Stainless Steel (5 types)

- Brass (6 types)

- Copper (4 types)

- Titanium (1 types)

- Mild Steel (3 types)

- Alloy Steel (3 types)

- Tool Steel (6 types)

- Spring Steel (1 types)

Plastic

- ABS (3 types)

- Polycarbonate (PC) (1 types)

- Nylon (2 types)

- Polypropylene (PP) (1 types)

- POM (1 types)

- PTFE (Teflon) (1 types)

- PMMA (Acrylic) (1 types)

- Polyethylene (PE) (1 types)

- PEEK (1 types)

- Bakelite (1 types)

- FR4 (1 types)

- Rubber (1 types)

A variety of CNC machined metal and plastic part options are available for an instant online quote. If you do not see the material stock you are looking for, please choose "Custom" under the material drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required.

Available Finishes

- Standard (As-Milled) (Ra 125μin)

- Anodized

- Black Oxide

- Bead Blast

- Spray Painting - High Gloss Paint

- Chrome Plating

- Nickel Plating

- Gold Plating

- Vacuum Plating - High Gloss Paint

- #1000 Sanding

- Laser Engraving

- Chemical Conversion Coat (Chem Film)

- Passivation

- Electropolished (Ra0.8µm, 32µin)

- Pickling

- Dyeing

- Bead Blast + Anodized Color

- Electrically Conductive Oxidation

- Brushed

- Spray Painting - Matt Paint

- Powder Coat

- Galvanization

- Silver Plating

- Tin Plating

- Vacuum Plating - Matt Paint

- Silkscreen

- Smooth Machining (Ra1.6µm, 63 µin)

- Electrophoresis

- Etching

- PVD (Physical Vapor Deposition)

- Others

CNC Orientation and Form General Tolerances

Unless we have agreed to other tolerances in your Quote, we will work to achieve and hold the tolerances noted below, which will vary per the primary manufacturing method you select.

(eg.:Round hole 10mm, tolerance +0.01—0.03mm)

- Part Length

- Orientation and Form Tolerance

- Angularity Tolerance

- 0 to 12"(300 mm)

- +/- 0.005" (0.125 mm)

- Angularity +/- ½ Degree

- 12" to 24"(600 mm)

- +/- 0.010" (0.250 mm)

- Angularity +/- ½ Degree

- 24" - 36"(900 mm)

- +/- 1/64" (0.016")(0.400 mm)

- Angularity +/- 1 Degree

- 36" - 60"(1500 mm)

- +/- 1/32" (0.031")

- Angularity +/- 1 Degree

- Over 60"

- +/- 1/16" (0.063")

- Angularity +/- 1 Degree

Size Limitations For CNC Machining

- Item

- Part Size / Dimension

- Maximal Part Size

- 1000 mm (40in)

- Minimal Part Size

- 2 mm (0.08 in)

- Minimal Diameter

- 0.3 mm (0.01 in)