Dongguan Qijia Precision Co., Ltd. is a CNC machining technology service provider dedicated to communication, medical, artificial intelligence, automobile and other high-precision parts. I have been mainly engaged in the high-precision hardware industry for over 15 years. We have over 50 high-precision three axis, four axis, and five axis CNC machines imported from Japan and Taiwan. We are the only factory with Raytheon 3D machines, 4 aluminum alloy die-casting machines, and 8 zinc alloy die-casting machines; 6 CNC lathes and 15 automatic lathes; 10 forging equipment; And equipped with dozens of auxiliary processing equipment. At the same time, it is equipped with 3D, 2D, and in testing equipment such as avionics and 3D microscopes; The production and testing equipment is very complete, which can meet the various needs of customers. We have great advantages in quality and technology, with reasonable prices and a delivery time of only 7-15 days. We will provide samples within 3-7 days.

You choose our strengths:

1. Significant discounts on transportation costs and conditions;

2. Quick response to quotations and delivery times;

3. Excellent mold designers and engineers with over 20 years of experience in graphic based mold production.

If you are interested in our products, please contact me!

High Efficiency - we can produce 1-1000 CNC milling and turning components in a day

Excellent Accuracy - as per customer demand, we will provide accurate measurement for each part

Exact Specifications - our automatic CNC machines and tools will perform the pre-programmed motions to get the required objects with exact parameters

Competitive Price - with advanced multi axis CNC machining service and strong production capacity, we can bring you the most cost-effective solutions

Quality Guaranteed - carefully selected blank materials and strict quality control system throughout the whole process

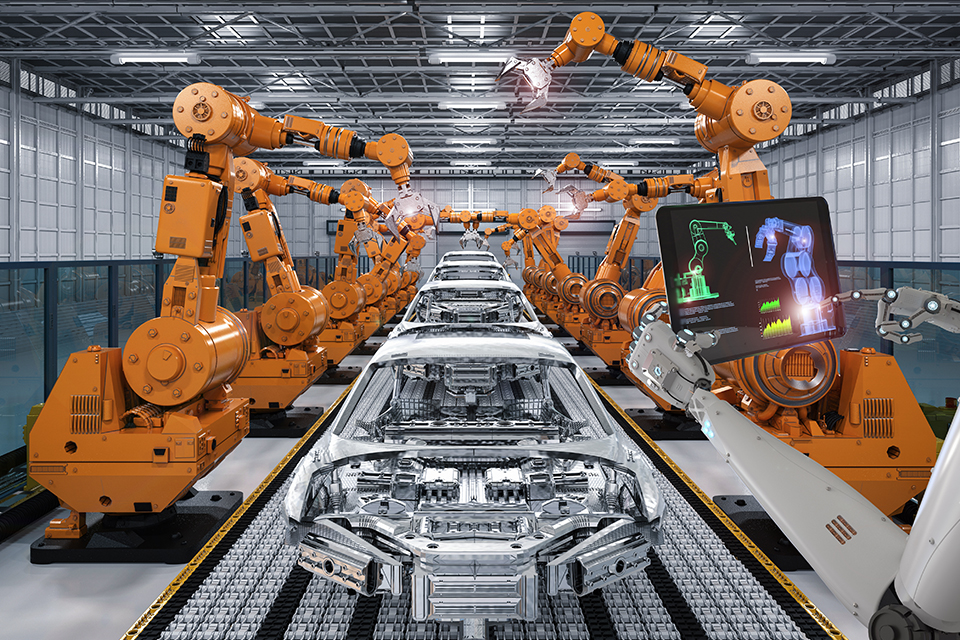

CNC machining is a manufacturing process suitable for various industries, including electronics, automotive, aerospace, and agriculture, and can produce a wide variety of products such as medical equipment, automobile engines, and aerospace. This process employs several different computer-controlled machining operations, including mechanical, chemical, electrical, and thermal processes, which remove the necessary materials from the workpiece to produce custom-designed parts or products.

CNC machining is a process that cutting tools are manipulated by computer to shape material block into the customized parts. Although CNC machining turning process provides many kinds of functions and operations, the basic principles are as below steps.

1.Designing a CAD model

2.Converting the CAD file to CNC program

3.Preparing the CNC machining machine

4.Executing the milling and turning operation

Dongguan Qijia Precision Technology Co., Ltd.